Differences Between HDPE 3408 vs. 4710

HDPE 4710 is an improved high-performance polyethylene compound for pressure pipe. Compared to conventional pressure piping materials such as HDPE 3408, HDPE 4710 has several characteristics that significantly improve its performance.

HDPE 4710 has a higher density than HDPE 3408, as well as increased tensile strength, stiffness, ductility, and resistance to fracture. These superior performance characteristics enable HDPE 4710 pipe to operate at higher internal pressures with greater resistance to chemical and environmental stresses and an increased lifespan.

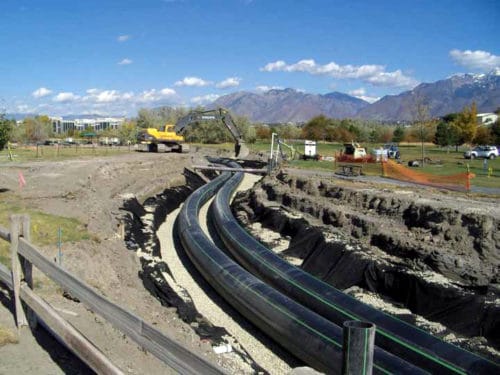

Explore WL Plastics’ HDPE pipe manufacturing capabilities.

Pressure Rating

HDPE 4710 pipes with superior ductility, resistance to fracture, and increased performance characteristics allow higher internal pressures than HDPE 3408 without reducing service life. The increase in pressure rating is due to several factors.

HDPE 4710 has significantly higher requirements for test data quality, analysis, and substantiation. HDPE 4710 is required to demonstrate ductility beyond 50 years, a condition not required for other materials. Variations between lots are also reduced, providing more consistent processing and reducing the extrusion quality variable as a design factor component.

The high performance of HDPE 4710 materials enables them to tolerate a higher surge pressure, and piping joints are fully restrained. HDPE 4710 has a 2 times pressure rating for occasional surge events and a 1.5 times pressure rating for recurring surge events. To learn more about pressure and surge allowance see our WL118 Pressure Ratings document.

The higher density, higher molecular weight, and higher SCG resistance of HDPE 4710 materials offer greater toughness, better resistance to abrasion and chemicals, and better high-temperature performance than HDPE 3408. These characteristics ensure that HDPE 4710 pipes are conservatively rated for a 100 year design life when properly designed, installed and operated.

Slow Crack Growth

Slow crack growth, or SCG, is the long-term failure mode for PE pressure piping materials. SCG is not due to brittleness but from internal pressure stresses, which cause cracks to develop and grow through the pipe wall. Testing of HDPE 4710 pipes has shown that a transition to SCG takes four times longer than HDPE 3408.

SCG resistance is determined using PENT resistance testing, which empirically correlates 25 to 35 hours PENT SCG resistance to 100 years in pressure gas service. HDPE 3408 is required to have a minimum SCG resistance of 10 hours, while HDPE 4710 must have at least 500 hours PENT SCG resistance, a 50 to 1 increase. Current HDPE 4710 materials exceed 10,000 hours of PENT SCG resistance.

Density

HDPE 4710 has a higher density than HDPE 3408. This higher density directly relates to an HDPE 4710 pipe’s increased tensile strength or its resistance to breaking under tension. The increase in density and tensile strength also provides added stiffness and improves the material’s resistance to chemicals.

HDPE 3408 with 2% carbon black have a density of 0.955 gm/cc compared to HDPE 4710 materials with 2% carbon black which have a density of 0.960 gm/cc. HDPE 4710 offers higher density, which results in improved tensile strength, better stiffness, and better chemical resistance.

Learn More About HDPE 4710 vs. HDPE 3408

HDPE 4710 offers many advantages over HDPE 3408, including higher density, reduced slow crack growth, and a higher pressure rating. With its enhanced performance characteristics, HDPE 4710 offers increased durability and lifespan when compared to HDPE 3408.

At WL Plastics, we are one of the largest manufacturers of HDPE pipe in North America. We offer our clients many unique advantages, with 8 state-of-the-art facilities located all across North America. We offer clients a broad mix of products, from 1/2 to 54-inch pipe, and have the experienced and dedicated team to meet your project needs with quick response times and speed to market. Learn more about the differences between HDPE 3408 and HDPE 4710 from our full report, “WL123 – High Performance PE 4710,” or contact us today for more information.