Oil & Gas Gathering

WL Plastics offers a wide selection of durable High Density Polyethylene (HDPE) pipe to meet the need of any oil and gas application.

Engineered for Performance: HDPE PE4710 Pipe in Oil and Gas Gathering

In the demanding environments of oil and gas gathering, pipeline integrity and longevity are paramount. WL Plastics' high-density polyethylene (HDPE) PE4710 pipe offers a superior solution, combining leak-free joints, exceptional durability, and resistance to hydrocarbon permeation. This advanced piping system outperforms traditional materials, reducing maintenance needs and extending service life without the requirement for coatings or corrosion prevention treatments.

Polyethylene pipe has been a proven solution in oil & gas gathering applications for over 35 years. Polyethylene pipe is the most cost effective solution to move process water, frac water, and produced oil & gas mediums. WL Plastic’s PE4710 pipe solutions are the next evolution of HDPE piping systems with improved physical properties, pressure ratings, and durability.

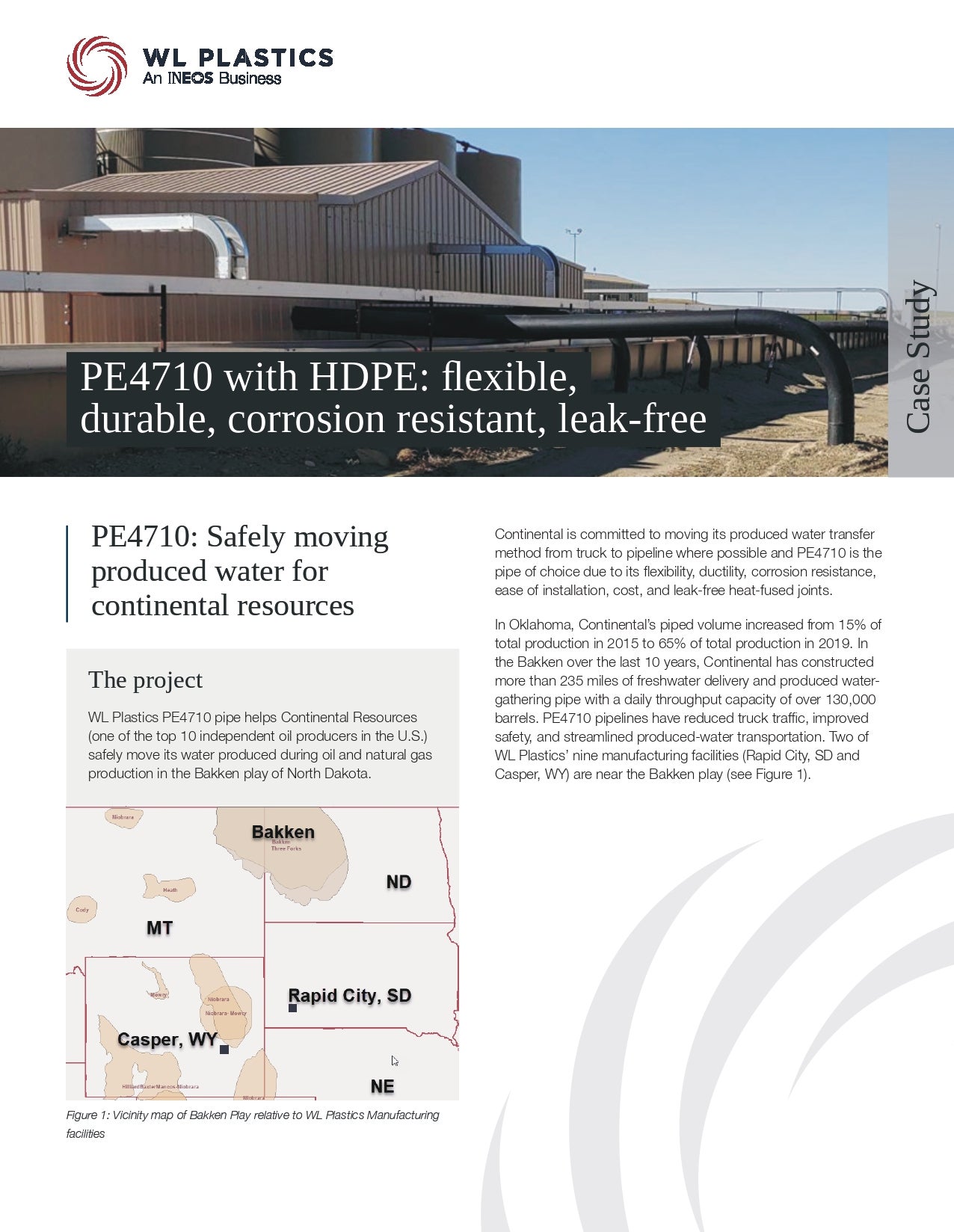

At WL Plastics, our HDPE PE4710 pipe is manufactured on the newest, and most efficient production equipment in the industry and to strict quality standards in accordance with API specification 15LE, ASTM D2513, and ASTM F2619. As a leading high density polyethylene pipe manufacturer, WL Plastics has 800 million lbs of annual pipe production capacity spread across 8 facilities with large storage yards strategically located throughout the United States to ensure cost effective, on-time delivery for our customer’s large projects.

Comprehensive HDPE Pipe Solutions for the Oil and Gas Industry

WL Plastics offers a diverse range of HDPE PE4710 pipe products tailored for oil and gas applications:

- Sizes: 3/4" to 54" IPS

- Pressure Ratings: Up to 500 psi

- Standards Compliance: API 15LE, ASTM D2513, ASTM F2619

- Features: Bimodal PE4710 composition, optional color striping, barcoding per ASTM F2897 for traceability

With ten strategically located manufacturing facilities across the United States, WL Plastics ensures timely delivery and support for projects of any scale. wlplastics.com

Case Studies for Oil & Gas Gathering

WL Plastics

Speak to Us About Your Next Project

Contact us today to speak to an expert about how polyethylene pipe could benefit your next project.

Contact Us